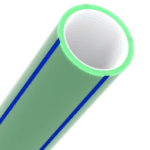

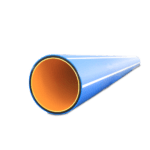

Double WALLED CORRUGATED HDPE (DWC) DUCT

BUILDING ROBUST INFRASTRUCTURE

For PERFECT CABLE PROTECTION

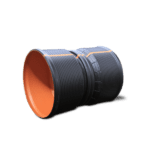

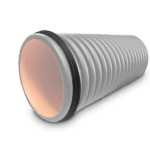

Ductrove’s Double Wall Corrugated Duct is an advanced profile duct design, manufactured from crystallized and virgin high-density polyethylene offering optimum strength and cost effectiveness. The annular corrugations combined with a smooth interior wall creates superior structural integrity. Its a superior solution for replacement of Galvanized Iron (G.I.), Reinforced Concrete Cement (R.C.C.) and Polyvinyl Chloride (PVC) pipes in Power & Fibre-Optic network.

This unique geometry, while making it light weighted, gives excellent mechanical properties like Sturdiness to withstand heavy external loads, high ring stiffness, superior impact strength and enhanced crush resistance. The smooth & sleek inner wall surface facilitates easy pulling of ducts and cables in DWC Duct

features

Ecological Footprint

DWC Duct is manufactured with less raw material in comparison with Standard HDPE, RCC & uPVC Pipes. The material used is Recyclable and the CO2 emission is 3-4 times lesser compared to concrete pipes during Production

Flexibility

DWC Ducts can easily withstand natural settlements without suffering cracks or leakages and has been engineered to bend without compromising the structural strength, unlike ducts made of rigid materials that are prone to cracking

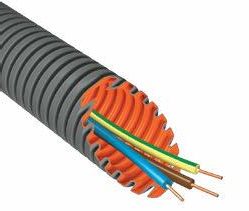

Options

We can manufacture DWC Ducts with Polyethylene/Nylon Rope, Pre-Installed Electrical Cables, Fire Retardant, UV & Rodent/Termite Resistant

Low Operation Cost

Lower transportation, handling & installation costs & no heavy-duty equipment required for installation

Lightweight and Strong

Strength is derived from corrugated design of the outer wall & saves up to 60 % in raw materials. It's low weight & can be installed in constrained areas

Long-life Performance

No abrasion to the inner wall of ducts & is resistant to acids and other aggressive fluids hence giving it a long lasting life

Supporting Accessories