SOLAR DUCT

CLOSER TO NATURE

FOR DELIVERING SUSTAINABLE PROJECTS

Solar & Wind energy continues to increase with the demand for more clean energy in today’s growing environmentally conscious society. Ductrove’s High Density Polyethylene (HDPE) duct plays a vital role in delivering sustainable projects by distributing energy.

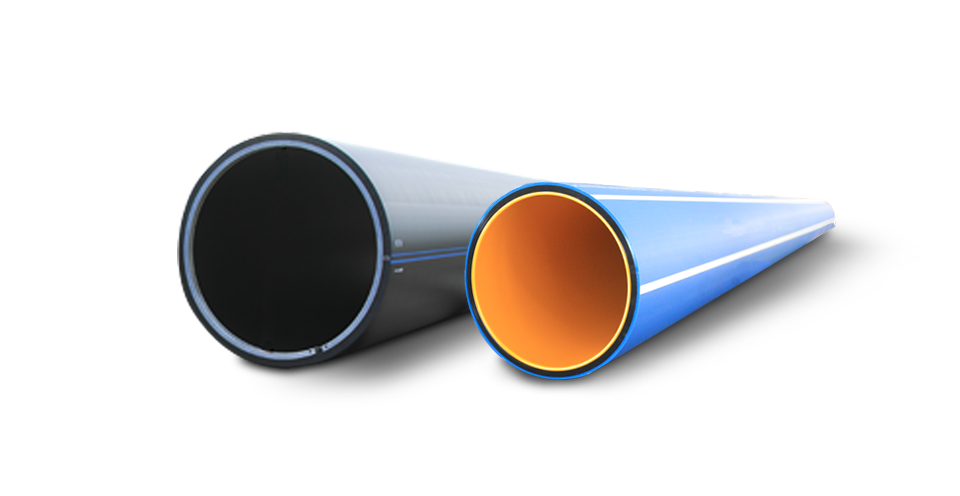

The Outer Layer of the Solar duct is made of Black HDPE reinforced with Carbon Black to make the duct Natural UV Resistant. Manufactured as per ASTM F2160 and NEMA TC-7, Our Solar Ducts gives extra protection for cables even in exposed conditions

features

UV Resistance

Solar Ducts are manufactured with Outer Layer Black in color which is a natural UV resistant color

Reduced Co-effecient of Friction

Solar Ducts have an inner Layer of Super smooth Silicon Coating which provides lower coefficient of friction to allow long cable pulls

Corrosion, Abrasion & Chemical Resistance

Solar Ducts have excellent corrosion resistance and is virtually inert. It does not need expensive maintenance or cathodic protection. It offers better overall resistance to corrosive acids, bases and salts than most piping materials. In addition, polyethylene is unaffected by bacteria, fungi and the most “aggressive” naturally occurring soils. It has good resistance to many organic substances, such as solvents and fuels.

Flexibility

Solar HDPE ducts are sturdy yet flexible enough to take bends and turns minimizing the need for joints, requiring lesser fittings and accessories ensuring reduced wastage of ducts.

High Temperature Resistance

The ducts can withstand cable temperatures from -20 degrees C to 90 degree C

Light Weight

Solar HDPE Conduits are produced in coils. Made from materials about one-eighth the density of steel, it is lightweight and does not require the use of heavy lifting equipment for installation. Since HDPE is not a brittle material, it can be installed with bends over uneven terrain easily in continuous lengths without additional welds or couplings.

Supporting Accessories